PLASTIC INJECTION MOLDING

SINCE 1983

Who We Are

KUKJEPLASTICS, founded in 1983, is a specialist in plastic injection molding and mold manufacturing. With over 40 years of experience, we have been offering a one-stop solution for product planning, design, mold design, and production in the plastic manufacturing industry.

KUKJEPLASTICS has earned trust from a diverse clientele by ensuring both exceptional quality and reasonable production costs, all attributed to our technical expertise and advanced automation equipment. KUKJEPLASTICS proudly boasts industry-leading technological capabilities in the fields of automotive accessories, infant products, medical equipment, and industrial products, supported by extensive experience across a spectrum of polymers including PP, PE, PC, ABS, and TPE.

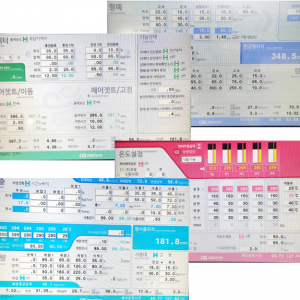

Numbers Speak

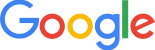

Mold Development

Molds are the beginning and end of quality!

No matter how excellent a product is, if the quality of the mold is low, it can lead to significant risks in terms of quality control, productivity, and mold management during the mass production process. Therefore, entrust the first button of product development to KUKJEPLASTICS, which not only possesses extensive expertise in molds but also excels in injection molding.

Product & Mold Design

Mold Manufacturing

Trial Production & Mold Stabilization

Injection Molding

The technical pride of KUKJEPLASTICS lies precisely in its excellent injection molding capabilities.

Many customers who had previously failed to produce products or faced unstable product quality elsewhere have found success in product development with us. Our injection molding expertise, driven by long-standing know-how, meticulous control of molding conditions, and unwavering commitment to quality, enables this success.

- Manufacturing Process

Material Recipe

We develop blending formulas for raw materials, pigments, and additives tailored to the characteristics of products such as appearance and purpose.

Molding Control

Fine-tuning dozens of molding conditions to discover the optimal conditions for meeting customer quality requirements.

Post-processing / Testing / Packaging

Precision post-processing and rigorous quality testing with colorimeters, microscopes, precision scales, and more, all ensure 100% quality completion.

Material Recipe Development

KUKJEPLASTICS sources high-performance engineering materials domestically and internationally,

formulating customized recipes to maximize product performance.

- Material Characteristics

Nylon

High shrinkage compared to strength makes precise design challenging. Careful material drying and management are necessary to address gas generation. Annealing post-molding reduces resin crystallinity, preventing brittleness.

TPE

Given the extensive variety, companies inexperienced in TPE may struggle to procure suitable materials, with specialized equipment required due to its demanding aesthetic standards. TPE is among KUKJEPLASTICS' top materials.

PC

Customized molding machines with specific screw types are essential, particularly for high-quality exterior products and high-functionality products. KUKJEPLASTICS currently uses PC in lenses, automotive parts, medical equipment, and household appliances.

ABS/PP/PE

As the most versatile material, its types and blending ratios vary widely, requiring extensive expertise in recipe development. KUKJEPLASTICS currently utilizes this material in producing masks for daily and industrial use, toys, and household goods.

Functional Additives

It confers various properties like impact, abrasion, scratch, heat, UV resistance, antistatic properties, gloss, friction coefficient, dimensional stability, and electrical conductivity. However, even small amounts significantly broaden molding conditions, increasing the challenge of quality stability.

Polyurethane / PBT

Used in industrial wheels, automotive accessories, and mobile phone cases for its soft yet tough properties and high wear resistance. However, due to its poor formability, expertise is required in designing the ejection method during mold design.

Facilities

Products

Baby Products

Life & Industrial Masks

Medical Equipment

Kids Toys

Home & Appliances

Industrial Products

Quotation Inquiry

Please fill out the form below, and we will contact you the same day!

(Attaching product drawings/business proposals will enable us to respond promptly and in detail.)