PLASTIC INJECTION MOLDING

SINCE 1983

Who We Are

KUKJEPLASTICS, founded in 1983, is a specialist in plastic injection molding and mold manufacturing.

With over 40 years of experience, we provide a one-stop solution for product planning, mold design, and mass production in the plastic manufacturing industry.

Our commitment to exceptional quality and cost-efficiency has earned the trust of clients across diverse industries. Backed by deep technical expertise and advanced automation, KUKJEPLASTICS offers industry-leading capabilities in automotive accessories, infant care products, medical devices, and industrial components. We work with a wide range of polymers including PP, PC, ABS, PA and TPE.

Numbers Speak

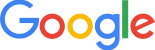

Mold Development

Everything about quality begins with the mold!

Even the most outstanding product can face serious challenges in quality control, productivity, and mold maintenance if the mold itself is not up to standard.

That’s why the first step in product development should begin with KUKJEPLASTICS a trusted partner with deep expertise in both mold making and injection molding.

Product & Mold Design

Mold Manufacturing

Trial Production & Mold Stabilization

Injection Molding

At KUKJEPLASTICS, our technical strength lies in our exceptional injection molding capabilities.

Many clients who struggled with product failures or inconsistent quality elsewhere have achieved success through our support. This is made possible by our decades of experience, precise control of molding conditions, and an unwavering commitment to quality.

- Manufacturing Process

Material Formulation

We develop customized blending formulas for resins, pigments, and additives tailored to meet specific product requirements such as appearance, durability, and functionality.

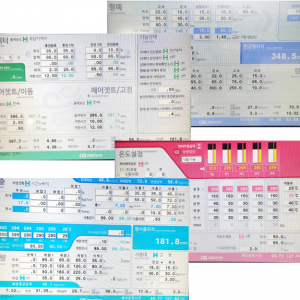

Molding Condition Optimization

We precisely adjust a wide range of molding parameters to identify the ideal settings that ensure consistent, high-quality results tailored to customer expectations.

Post-Processing, Quality Testing & Packaging

From precise finishing work to rigorous inspections using colorimeters, microscopes, and precision scales we ensure every product meets the highest standards before packaging.

Material Formulation Expertise

KUKJEPLASTICS sources high-performance engineering materials both domestically and internationally. We then develop customized formulations to maximize product performance.

- Material Characteristics

Nylon

Due to its high shrinkage relative to strength, precise mold design can be difficult. Proper drying and material handling are essential to minimize gas generation. Post-molding annealing reduces crystallinity, helping to prevent brittleness in the final product.

TPE

With its wide range of formulations, TPE can be difficult to source and process especially for companies without specialized equipment to meet its strict appearance standards. TPE is one of KUKJEPLASTICS’ core materials, supported by deep processing expertise.

PC

High-quality exterior and high-performance products require customized molding machines equipped with specialized screw types. KUKJEPLASTICS utilizes PC materials in lenses, automotive parts, medical devices, and household appliances.

ABS/PP/PE

As one of the most versatile materials, it requires significant expertise to formulate the right type and blending ratio. KUKJEPLASTICS leverages this material in the production of everyday and industrial masks, toys, and household items.

Functional Additives

It offers various functional benefits such as impact, abrasion, heat, and UV resistance, along with antistatic effects, gloss, friction control, stability, and conductivity. Even small amounts can significantly increase molding variables, complicating consistent quality.

Polyurethane / PBT

Commonly used in industrial wheels, automotive accessories, and mobile phone cases, this material offers a unique balance of softness, toughness, and excellent wear resistance. However, its low formability requires expert consideration of ejection methods during mold design.

Facilities

Products

Infanct & Toddler Care

Daily & Industrial Masks

Medical Devices & Components

Lifestyle Products

Automotive Accessories

Children's Play Items

Food Packaging

Industrial Products

Quotation Inquiry

Kindly complete the form below, and our team will respond within the same business day!

(Providing product drawings or business proposals will help us deliver a faster and more accurate response.)